Nowadays, people are generally a lot more conscious of their impact on the environment.

We’re seeing plastic straws switched out for paper ones, and disposable coffee cups swapped for reusable mugs – and perhaps the easiest way for the average person to help save the planet is the simple act of recycling.

But have you ever wondered where these recyclable products end up, once you’ve discarded them?

A lot of recycling from the Narrabri, Moree and Gwydir shires is handled by the team at our local Challenge Recycling, who sort various materials by hand at their Arnold Street processing plant.

Aluminium is crushed, cubed and sent off to Brisbane.

Meanwhile PET plastics are recycled back into new products.

Cardboard is flattened and cubed before being sent off to be manufactured into recycled items.

The work done by Challenge is usually the first step, followed by a variety of organisations processing the materials further, before it ends up with Australian Recycled Plastics (ARP) who send it on to be remade into something new.

It’s a great asset to Narrabri, not only in terms of environmentally-friendly waste practices.

The business is also the town’s only Australian Disability Enterprise (ADE), which provides opportunities for people with a disability to contribute and connect to their local community.

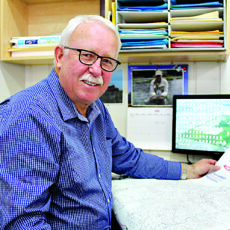

As the manager of Narrabri’s Challenge Recycling – Matt Keeffe – says, it’s about so much more than offering supported employment for people with disabilities.

“We want to help grow their confidence and skillset,” he said.

“So, rather than just assigning our team members with tasks, we also provide the training and support they need to succeed in the role.”

As well as the practical on-site training that Challenge provides – such as forklift accreditations, one-on-one learning and specialist equipment coaching – team members are also provided with education into life skills.

“Our approach is holistic, so we help them with everyday skills such as cooking, cleaning, grooming, punctuality and more,” Mr Keeffe said.

“Our employees can see us working alongside them, supporting their personal journey in both physical and mental development.”

The recycling plant hires people living with all kinds of disabilities and caters their training to the individual.

He also explained that, for some of his employees, working with Challenge is simply a steppingstone for them to build on their skill level and confidence before moving into open employment in the future.

“Everyone has their own goals and aspirations, and Challenge is here to help them reach whatever it is they hope to achieve,” he said.

“Whether it be moving up our levels internally through training, learning a new skill in a specific area of interest, or developing the confidence to go beyond disability employment into open employment.”

This employee-focused approach has resulted in high levels of job satisfaction, which has further expanded the enterprise’s capabilities.

“We don’t want to be a one-trick pony,” said Mr Keeffe.

“As well as the various materials we process for recycling, including the cardboard pick-up collection service we run around town, we’re always exploring other potential new service offerings.”

“For example, we embraced the Return and Earn system when it came to Narrabri, and we offer confidential shredding for business and individuals.”

“And this ability to expand our reach is a direct result of our team’s hard work.”

Mr Keeffe credits his employees for the many improvements made to the business over time.

“Some of them have been here for years so, when they come to us with an idea to improve efficiency and output, we know they’re speaking from experience,” he said.

“By listening to them, we’ve been able to make positive changes to our approach that have ultimately helped grow the business.”

“For example, when our aluminium cubes are stacked, there’s an employee who takes responsibility for ensuring the rows have 10 bales each row , because he knows this makes stocktaking and transporting the material that much easier, another employee suggested modification of a part of the process which improved efficiency.”

But Mr Keeffe says improving output for profit isn’t the primary focus at Challenge.

“We’re not designed to make money, we’re more concerned with being sustainable,” he said.

“Both in terms of minimising harm to the planet, and ensuring our business practices can sustain our growing employment numbers.”

As Challenge Recycling’s responsibilities grow, so too does the number of people employed by the plant.

“But we’re always welcoming new team members who are looking for new opportunities to explore a supported wage,” Mr Keeffe said.

“If you have areas you’d like to work on, for example if you struggle with literacy but are interested in hands-on work, we can help with training to support those goals.

“If you’re on the NDIS and DSP, we encourage you to apply for work with us.”

“In fact, we’ve recently started working with Best Employment to look at potential new employees, including school leavers.”

Mr Keeffe says everyone at Challenge is dedicated to their work, and each other.

“I’ve worked for a lot of companies, but I’ve never seen a team quite this tight-knit,” he said.

“It’s like a family, where everyone is working together towards a common goal.”

Mr Keeffe says he’d love to see his team’s commitment to recycling spread across the local area.

“Our team works really hard, but they can’t do it alone – we need everyone in the Narrabri Shire and surrounds to do their bit,” he said.

“For example, if you’re heading along to a Return and Earn, make sure you correctly dispose of the plastic bag or cardboard box you were carrying your recyclables in.”

“Or, if you’re not totally sure what bin to use for certain materials, research so you can make the correct decision.”

“The Narrabri Shire Council website outlines all of the information you need about recycling, but if you’re still unsure the Challenge team is always happy to take phone calls from the public to answer your questions.

“If we’re all a little bit more mindful of our impact, we can make a big difference.”

See more like this:

- Recycling facility set for expansion thanks to grant

- Narrabri business grows as a major recycling hub

- Wee Waa High School launch recycling program